BURMON ICF CONNECTOR SYSTEM

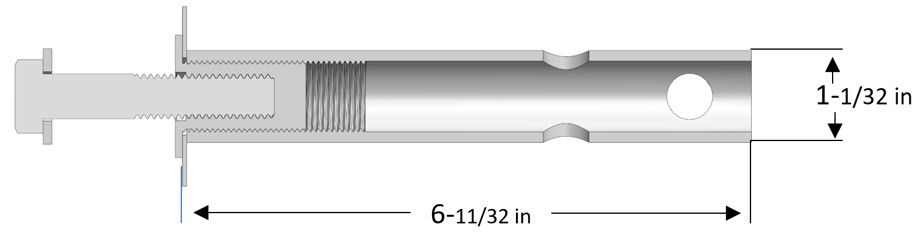

The cylinder bolt assembly is engineered with high capacity sheer points, which more efficiently absorbs the energy of the unsupported load transfer span, between the polystyrene inner and outer ICF wall. The embedded legs of the cylinder tube have openings to receive concrete and rebar (optional) and the high capacity bolts connect directly to the concrete within the ICF wall, enhancing strength, stiffness of connection, function and durability. US Patent Application 17/120,457.

Share On: